Technical

Acclimation

Before installing your hardwood floor, it must first be properly acclimated. This means that the moisture levels need to be regulated in order to avoid any damage by shrinking or expanding after the flooring has been laid.

After your new flooring has been delivered, it is key to store it in a climate-controlled area of the home you will be installing it in for a minimum of 72 hours. NEVER store your flooring in your garage, basement, barn, or shed! The floor must be in home with the furnace on (if winter). If the flooring is being installed in a new build, it is recommended for the flooring to acclimate for 5-7 days, as the moisture level in the building may not be regulated yet. Engineered flooring may take longer to acclimate, therefore a period of up to 5 days will be needed in order to reach proper humidity levels.

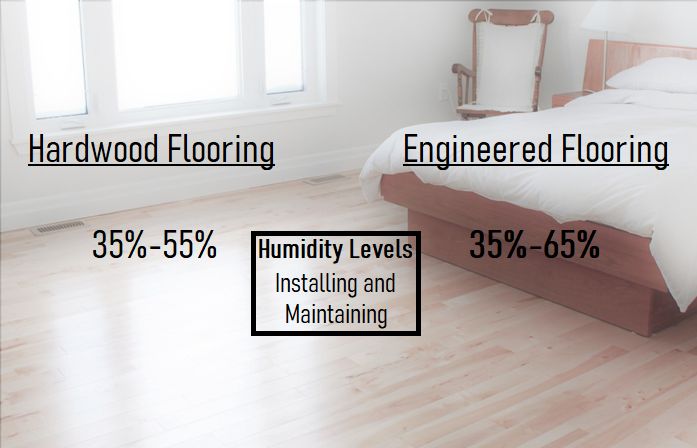

The ideal humidity level for wood flooring depends on what type of wood you are installing, but generally a level between 35-55% is ideal. This is also the level that the flooring should be maintained, as well as a temperature between 60 – 80 degrees Fahrenheit.

We recommend for any new builds have the dehumidifier running once the dry wall is installed because of the all the water that is taken on during the building process.

Humidity and your Wood Flooring

When it comes to your hardwood floors, humidity can have the biggest impact, especially for new homes when moisture levels are not yet regulated. It is super important when laying down hardwood flooring in a new home, that you first maintain the proper humidity level in order to prevent irreversible damage to your wood floors.

The right humidity level is also important to your health and well-being. A healthy humidity level is between about 40% - 50%. Low humidity levels, more common in the winter, can cause respiratory infections, while high humidity levels in the summer can cause mold, dust mites and bacterial viruses.

Our Canadian winters can bring some extreme weather, which causes dryer humidity levels. With the residential construction market at its highest rate (and ever increasing), construction generally continues steadily throughout the winter. This makes it even more important to be diligent when installing hardwood floors.

In dryer climate, hardwood flooring loses moisture, which causes the planks to contract. Gaps can appear between the boards as normal, however in extreme dryness, the boards can become brittle and can even cause splintering. This is when the center or edges of the board crack causing irreversible damage. It is recommended in the winter months that the home be regulated with a humidifier to prevent this from happening.

Installing flooring in a dry climate means that the hardwood planks will already be contracted. They will then expand when the humidity increases, meaning boards will gap to compensate and can cup. Immediate action is required to prevent permanent damage. This is where a humidifier is ideal.

Summer time can bring more moisture in the air, giving your home a higher humidity level. The planks in your hardwood floors absorb this moisture and will expand. Too much expansion can put pressure between boards and in turn cause the flooring to cup, meaning the edges of the planks will raise higher than the center. This can cause buckling, which can be irreversible damage to your hardwood flooring. Using a dehumidifier or running your Ac at a regular 20-24 celsius in those higher humidity levels can prevent this from happening.

Generally in a new house build, the humidity levels are higher. This is because of the components used to build (concrete and wood) are curing, expelling moisture into the air inside your home. Hardwood flooring should be one of the last things installed when building a new home, giving your house time to settle, but a good contractor will help to make sure of a good climate before acclimating and installing your floors.

A helpful tool you can use is a hygrometer, which will measure the percentage of humidity in the air. A simple hygrometer can retail for about $10 on Amazon, helping you determine how to go about regulating your home’s humidity climate.

Take a look below to see about how much humidity your hardwood and engineered floors can take!

General Site Inspection

Hardwood Flooring should be one of the last products installed at a construction site. All work involving water or moisture (plumbing, masonry work, drywall taping, etc.) should be complete before wood flooring is delivered to the job site.

Protect your flooring from high humidity at all times. Never unload your flooring in heavy rain or heavy snow.

Your job site should have a consistent room temperature of 60-70°F (16-22°C) and humidity of 40-55% for a minimum of five days prior to the installation of your hardwood flooring product. This environment should be maintained continuously thereafter.